Symbios Solutions provides quality Automation Engineering Services. We can help our partners by providing automated systems and solutions. There are various fields of Automation in which our experienced and qualified engineers can assist which include Human Machine Interfaces for your equipment and PLC and fully or Semi-Automated production line.

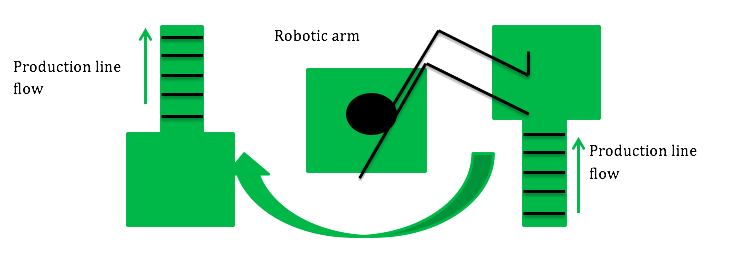

Symbios Solution can assist you in designing and developing a fully or semi-automated, robotic integrated solution. Automated production line not only assist in increasing the production but it also enhances the overall efficiency of the system, cuts down the costs and increases the quality as well. If you have a manual production line, we can design an automated system for your manual production line with robotic integration.

If you have a production line or an assembly line, this means you are producing items in bulk and bulk production means bulk maintenance and bulk attention as well. Isn’t that right? Automation is a start.