Organizations tend to get stuck with Analysis paralysis or faced with massive proliferation of excel factories that makes leadership view even the most sacrosanct reports with a suspicious eye.

Lean Six Sigma Green Belt program is a very powerful system-based approach. Six Sigma methodology helps you to understand your process variables and to assess the correlations between them, hence you can optimize these variables to maximize your output.

The Six Sigma methodology focuses on problem solving through the analysis of data using advanced statistical tools. If your organization’s focus is on quality improvement with an emphasis on problem solving to improve your service level, yield, process-variance, packaging losses, customer complaints, rejects or NCRs; start with Lean Six Sigma Green Belt.

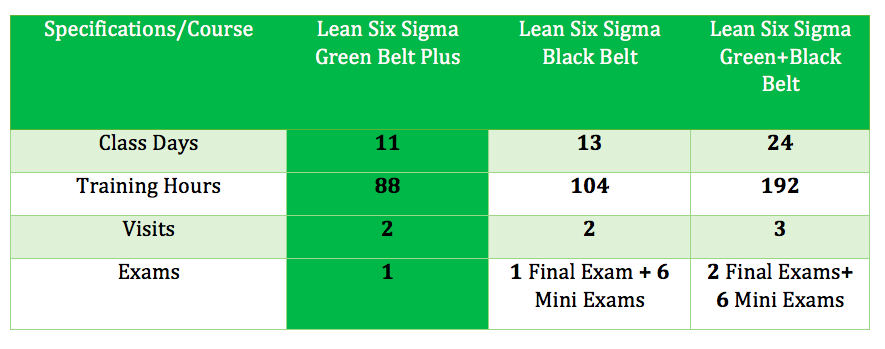

Our 11 days practical training program helps you to learn how to implement Six Sigma tools at your company. Learn from world class Black Belts and Master Black Belts how to implement Six Sigma reap real gains out of your project.

Our training programs are accredited from Council for Six Sigma Certification in USA.

https://www.sixsigmacouncil.org/